Success Story: Uno Minda’s Export Journey

Case Study

Success Story: Uno Minda’s Export Journey

Uno Minda Limited, founded in 1958, has grown into a leading global Tier-1 manufacturer and supplier of automotive solutions for original equipment manufacturers (OEMs). Today, the company designs and produces over 25 categories of vehicle components — from switches, lighting, acoustics and seating to alloy wheels, serving passenger cars, commercial vehicles, and two- and three-wheelers, for internal combustion engine (ICE) and electric/hybrid platforms. It holds a leadership position in India across almost all its product lines. Technology and innovation are at the core of Uno Minda’s culture: the organisation continuously pushes boundaries to remain at the forefront of emerging automotive trends.

Over the past six decades, Uno Minda has also built an international footprint. It operates over 74 manufacturing plants globally and maintains dozens of research and development (R&D) centres. These include facilities across India and major auto hubs in Asia and Europe, and in 2023 the company expanded its innovation network with a new R&D centre in the Czech Republic.

Uno Minda’s global network is supported by numerous joint ventures and technical agreements with renowned automakers in Japan, South Korea, Germany, and China. The group itself is structured as a conglomerate of many specialised companies, each an independent profit centre, which provides agility and focus in areas such as switches, lighting, or seating.

We interviewed Mr. Nirmal Minda, Executive Chairman at Uno Minda, to understand the company’s export branding journey, from its early export strategy and successes to its current global positioning and future plans. In the following sections, we share key takeaways from our discussion and excerpts from the interview.

Market entry and expansion

What motivated Uno Minda’s early move into exports? In 2023, the Chief Financial Officer (CFO) noted that the company aims to “double revenues from global business to act as a lever against domestic market fluctuations”. How did this strategy emerge, and what were the first steps the company took to implement this strategy?

The early overseas expansion of Uno Minda was driven by the long-term aim of becoming a stronger and more globally competitive business. The management realized that dependence on India alone would expose the company to local downturns and intense competition. Abroad, Uno Minda could diversify revenues, enter high-margin markets, and genuinely strengthen the business. In fact, by 2023, the company had even set a goal of doubling export revenues as a buffer from fluctuations domestically.

Competing in mature markets also forced Uno Minda to raise its game. Meeting stringent quality and technical standards in places like Europe and North America pushed the company to upgrade its manufacturing and R&D capabilities. This lifted quality across the board, benefitting its export products and domestic operations. Exposure to global trends, from electrification to advanced driver-assistance systems (ADAS), also gave Uno Minda early insights into emerging technologies.

In practice, the company focused on execution. It set up dedicated export lines in its plants and opened customer-facing offices in key regions (Europe, ASEAN, and others). This ensured products met local certifications and allowed Uno Minda to build direct relationships with global OEMs. Expanding overseas was never about chasing scale for its own sake; it was a strategic way to diversify, learn, and adapt so the company became stronger at home and abroad.

What were the key milestones and turning points in your export growth? Which events proved pivotal in expanding your global presence?

International forays of Uno Minda have always been deliberate and strategic. One of the initial steps undertaken included setting up plants in Indonesia (2005) and Vietnam (2009). Such facilities allowed Uno Minda a presence in ASEAN markets and to respond in close timing to local OEM demands in the region. With the establishment of these factories locally, the company could effectively serve customers in the region and build customer confidence as a local supplier to OEMs.

Another major turning point was cross-border acquisitions. In 2013, Uno Minda bought Spain’s Clarton Horn, a leading horn-system maker. This instantly opened doors to established customers in Europe and Latin America, along with Clarton’s R&D and manufacturing expertise in the EU. Six years later, in 2019, the German lighting specialist Delvis became part of the group. Delvis brought advanced lighting design and electronics know-how, helping Uno Minda enter the premium passenger-car segment. These acquisitions widened the product range and brought valuable technical know-how and credibility to the brand.

Over time, the company also developed a global network of R&D and engineering centres in Japan, Taiwan, Korea, Germany, Spain and recently the Czech Republic. This is to magnify innovation and be customer centric worldwide, especially in Europe and Asia. Milestones taken together, they show a clear strategy: Uno Minda has considered meaningful partnerships and technological gains instead of merely expanding in size.

Uno Minda’s ASEAN plants proved that it could be a local player in fast growing regions. Clarton unlocked European horns and gave instant credibility; Delvis injected premium lighting know-how. Each deal was chosen for strategic fit, not size, steadily deepening Uno Minda’s global presence and technology base.

Challenges in international expansion

What challenges did you face in international expansion? How did Uno Minda overcome such obstacles in practice?

Entering mature automotive markets came with significant challenges. Uno Minda was up against suppliers with decades of experience, scale, and strong OEM relationships, so it couldn’t rely on low costs alone. The company responded by raising its standards, it had to meet or exceed global quality, engineering, and delivery expectations right from the start.

Another obstacle to overcome was meeting the just-in-time (JIT) demands of international OEMs. To counteract this situation, Uno Minda established local assembly lines and warehousing facilities adjacent to major customer plants. Such hybrid arrangements (where core components are manufactured in India, and lead assembly is carried on overseas) definitely ensured deliveries made in time and minimum disturbance to OEM supply chains, while maintaining costs.

Building technological credibility was also tough. In its early years, some global customers doubted the design and innovation capabilities of Uno Minda. The company solved these problems by heavily investing in its global R&D network and making key acquisitions (Delvis, Germany) to enhance technological competence. It later went on to set up, among others, advanced testing labs as well as develop co-engineered projects with OEMs. In due course, such measures showed the capability of the company to innovate and built trust in export markets.

Uno Minda faced entrenched rivals, exacting JIT delivery rules, and doubts over its engineering depth. The response: invest in best-in-class quality systems, place final assembly and warehousing near key OEMs, and build a network of over 30 R&D centres, bolstered by acquisitions such as Delvis. Over time, consistent delivery turned sceptics into advocates.

Aligning with the “Make in India” initiative

How is Uno Minda aligning with the “Make in India” initiative to not only strengthen its domestic manufacturing capabilities but also enhance its competitiveness in global markets?

Uno Minda has embraced the “Make in India” initiative as a chance to raise its manufacturing game. Across its plants in India, the company has invested in modernisation, adding automation, advanced digital technologies, and lean processes so that what is made in India is globally competitive in quality, design, and performance (not just cost). The idea is that every part should be world-class, whether it is bound for the domestic market or export.

The cornerstone of this approach is the deep localisation of technology. Uno Minda is localising critical technologies to resist import dependence and boost the domestic supply chain. To this end, it has developed its R&D efforts and adopted a partnering approach with international technology leaders to co-develop advanced products in India. Resulting in India-engineered solutions for export markets, it is in tune with the vision of India as an innovation hub. By putting world-class manufacturing on par with homegrown innovation, Uno Minda takes advantage of the term “Make in India” as

a competitive motif on the global stage. Using these partner networks along with internal R&D, the company undertakes to create “India-engineered” products for the global market in line with the vision of India being an innovation hub, rather than a manufacturing base.

Localisation and market adaptation

How did you localise products and marketing for different markets? You already supply to major European OEMs (e.g. VW, BMW) on a limited range. What adaptations were needed in product design, packaging, or branding to meet the standards and preferences of each region? Can you give examples of how a product was tailored for a specific export market?

Localisation has been a critical part of Uno Minda’s export strategy. The company aimed at setting up marketing and liaison offices in all strategic regions, including Europe, Japan, and ASEAN, to absorb customer insights and handle relationships in real time. It also created regional warehousing and assembly lines, which guaranteed faster response times to ensure OEMs hold their deliveries in supply chain commitments.

Product-wise, major changes were being done depending on the local requirements. For instance, in serving the European customers, Uno Minda co-developed heated handlebar grips, light temperature-controlled seat modules for two-wheeler products, especially suited for cold winter climates.

In each case, the company worked closely with OEMs to tweak designs, materials or packaging so that the parts met local regulations and customer expectations seamlessly.

Role of subsidiaries

What role did subsidiaries play? Acquisitions such as Clarton in Spain and Delvis in Germany, and operations in Indonesia and Vietnam gave Uno Minda local footholds. How have these entities helped with distribution, customer relationships or on-the-ground support in key regions?

Subsidiaries, including acquisitions and overseas plants, have been vital in Uno Minda’s global expansion. When the company acquired Clarton Horn in Spain and Delvis GmbH in Germany, it gained immediate access to those companies’ customers and technical expertise.

For example, Clarton was a European leader in horn systems, its experienced engineering team and testing facilities became a knowledge centre for Uno Minda. Delvis, with its advanced lighting focus, brought high-end design and electronics expertise, allowing Uno Minda to compete in the premium car segment.

Apart from the acquisitions, other plants, such as those in Indonesia or Vietnam, served the same function. These factories are like local subsidiaries making parts close to the major OEM hubs, allowing just-in-time deliveries and custom services. Having local manufacturing and manpower builds confidence among consumers, as it is a symbol of commitment and also, the presence of on-the-ground support.

In effect, these subsidiaries and acquisitions served as bridges between Uno Minda and regional markets. They combined local market understanding with Uno Minda’s technical strength, helping it innovates and grow more effectively in each geography.

Building a global brand

As Uno Minda’s international business has grown, the company has recognised that marketing and customer engagement are critical to success abroad.

It has put effort into understanding diverse markets and tailoring its approach accordingly.

This includes establishing local teams and infrastructure to bridge cultural gaps, gather market intelligence, and build close relationships with overseas OEMs.

In India, you enjoy strong brand recall in major product categories. How do you build recognition and trust abroad, where customers are less familiar with your name?

Building a brand abroad started with earning trust through performance. Uno Minda focused on delivering high-quality, on-time shipments and collaborating closely with customers. In new markets, it often began with pilot runs and earned key certifications to prove it could meet global standards. Each successful delivery and positive OEM reference helped Uno Minda’s reputation grow gradually. By consistently delivering products that meet or exceed stringent global specifications, and by ensuring on-time supply through local facilities or warehouses, Uno Minda has built a reputation as a dependable Tier-1 supplier.

Acquisitions also helped raise awareness. Products from Clarton and Delvis already carried strong local brands, so Uno Minda initially leveraged that goodwill. It kept the legacy brand names on the products while gradually introducing the Uno Minda mark. This dual-brand approach made European customers comfortable during the transition.

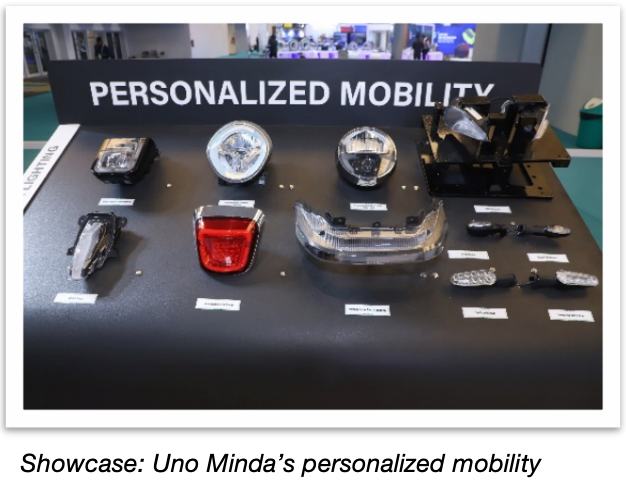

Finally, the company invested in visibility. It showcased its technology and sustainability credentials at international auto shows, trade fairs, and OEM supplier events.

Performance came first: deliver on spec, on time. Dual branding kept familiar local names alive while gradually introducing Uno Minda. Regular presence at auto shows and supplier summits showcased technology and sustainability, steadily raising awareness.

R&D and innovation

Innovation and digital transformation have become key drivers of Uno Minda’s export strategy.

The company leverages its global R&D network to design products that meet the specialised needs of international customers.At the same time, it uses digital channels and data analytics to engage with global markets more effectively.

In this section, we explore how Uno Minda’s R&D and technology initiatives support its international growth and what plans lie ahead.

What has been the role of R&D and innovation in your exports? Uno Minda now has R&D engineering centres in India, Europe, and Asia. How has this global R&D network driven product innovation for international customers? Can you cite examples of new products or technologies that were developed specifically to win export orders?

R&D and innovation are central to Uno Minda’s export success. The company has built an integrated R&D network across India, Europe, and Asia, so engineers and designers worldwide can collaborate on new products. This means Uno Minda can quickly adapt to different markets and push technology boundaries.

For example, its European engineering teams have developed advanced lighting solutions from OLED tail lamps to pixelated LED modules for premium European carmakers. Another standout is a CAN-LIN-based based “smart switch” co-developed for a US two-wheeler OEM, which includes wireless communication and self-diagnostic features. A third example is the Starlight Headliner created for a prestigious British luxury automobile manufacturer. This bespoke feature uses hundreds of fibre-optic lights to recreate a starry night sky on the vehicle’s roof lining. It showcases Uno Minda’s craftsmanship and precision engineering, and it demonstrates the company’s ability to deliver high-end, custom interior components.

In essence, a robust global R&D framework not only fuels product differentiation but also positions Uno Minda as a trusted innovation partner for international OEMs. By staying close to customer needs and investing in cutting-edge design, the company ensures its export products lead with new technologies.

Digital strategy and analytics

How have digital channels and data analytics been used in your export strategy?

Uno Minda has also turned to digital tools to drive its export strategy. The company uses online platforms to raise its international profile and engage customers, for instance, virtual product demos, online marketing and digital communication channels help showcase capabilities to OEMs worldwide. This expands Uno Minda’s visibility far beyond what traditional sales calls could achieve.

On the analytics side, Uno Minda uses data-driven insights to optimise its export supply chain. Advanced forecasting and inventory-planning tools help ensure the company meets Just-In-Time delivery commitments which is a critical capability for global OEMs. The company also tracks regional market trends, customer preferences and competitor activity using analytics. This intelligence lets Uno Minda tailor its product offerings to each market and identify new white-space opportunities where customer needs are unmet.

The digital-first approach makes Uno Minda agile and customer-focused. Rapid feedback loops mean it can iterate products quickly, and data-driven decisions ensure the company remains responsive to export market needs and ahead of competitors.

Outlook and advice

What’s next for Uno Minda’s international plans, and what advice would you give others? Looking ahead, which new geographies or product segments (e.g. EV components, higher-end systems) are you targeting? Will you invest in more overseas facilities or deepen ASEAN/India manufacturing as suggested?

Looking ahead, Uno Minda will keep scaling its international business, with a focus on profitability and sustainability. The company plans to deepen its exports of existing products, especially switches and seating, where it already sees strong demand and to grow in high-potential segments such as automotive lighting, alloy wheels and EV components. It sees the most value in cost-competitive regions, so it will continue expanding capacity in ASEAN, as shown by the new two-wheeler lighting line in Vietnam and the upcoming expansion of its Indonesian facilities. It does not plan to build factories in high cost developed markets, instead leveraging India’s competitiveness and its ASEAN footprint to meet global demand.

The company emphasises a balanced, strategic approach. It suggests keeping a sharp eye on cost competitiveness and building flexible, modular supply chains. Developing deep local understanding and strong customer relationships is vital. Above all, expansion should be underpinned by robust technology and innovation. In practice, this means choosing markets and segments carefully, investing in R&D, and using a mix of exports and regional production to remain agile and resilient in a complex global landscape.

Lessons for exporters

Finally, what lessons from your journey would you share with other Indian component makers aiming to grow via exports?

Uno Minda’s experience offers several lessons for other companies. First, maintain a sharp focus on cost competitiveness and build modular, flexible supply chains that can respond quickly to demand changes. Invest time and resources in understanding local markets, their customer preferences, regulations and cultural nuances and consider setting up local teams or partnerships to bridge any gaps. Above all, anchor your expansion on strong technology and customer relationships.

Disclaimer: This information has been collected through secondary research. The views expressed by the spokespersons are their own and do not necessarily reflect those of IBEF. IBEF is not responsible for any errors in the same.

Get In Touch

Your input is valuable in shaping the future of the IBEF Export Newsletter! Take a moment to share your thoughts and help us bring you more relevant insights, success stories, and export branding strategies.

Contact & Subscriptions: Contact Us

Email us at: info.brandindia@ibef.org

Call: +91 11 43845501