SEARCH

RECENT POSTS

Categories

- Agriculture (32)

- Automobiles (19)

- Banking and Financial services (34)

- Consumer Markets (51)

- Defence (6)

- Ecommerce (21)

- Economy (69)

- Education (13)

- Engineering (6)

- Exports (21)

- Healthcare (25)

- India Inc. (8)

- Infrastructure (29)

- Manufacturing (28)

- Media and Entertainment (15)

- Micro, Small & Medium Enterprises (MSMEs) (15)

- Miscellaneous (30)

- Perspectives from India (34)

- Pharmaceuticals (4)

- Railways (4)

- Real Estate (17)

- Renewable Energy (17)

- Research and Development (9)

- Retail (1)

- Services (6)

- Startups (15)

- Technology (56)

- Textiles (7)

- Tourism (14)

- Trade (5)

How the Chemical Industry is preparing for a Sustainable Future

- Dec 09, 2025, 10:00

- Manufacturing

- IBEF

In India, the chemical industry remains one of the most influential sectors for manufacturing, contributing about 7% of the GDP while providing vital inputs to the agriculture, pharmaceuticals, textiles, auto, and construction industries. India ranks as the sixth most significant chemical producer in the world and in Asia, the third. It manufactures over 80,000 commercial products in bulk chemicals, specialty chemicals, agrochemicals, petrochemicals, polymers, and fertilisers. These numbers are powerful foundation in terms of innovation and expansion since the industry has established a good global standing in dyes, agrochemicals, generics, and vaccines. India is one of the countries that the chemical industry is focusing on for the implementation of digital transformation.

India is adopting green chemistry, circular economy, and digital transformation to minimise the future harmful effects of the chemical industry. These strategies focus on minimising the adverse effects of the environment, and increasing the efficiency of resource use, and shaping a sustainable future. The chemical industry of India has developed strategies that will deal with food security, climate change, and plastic waste in the world. These strategies will indirectly make the country competitive and improve the economy.

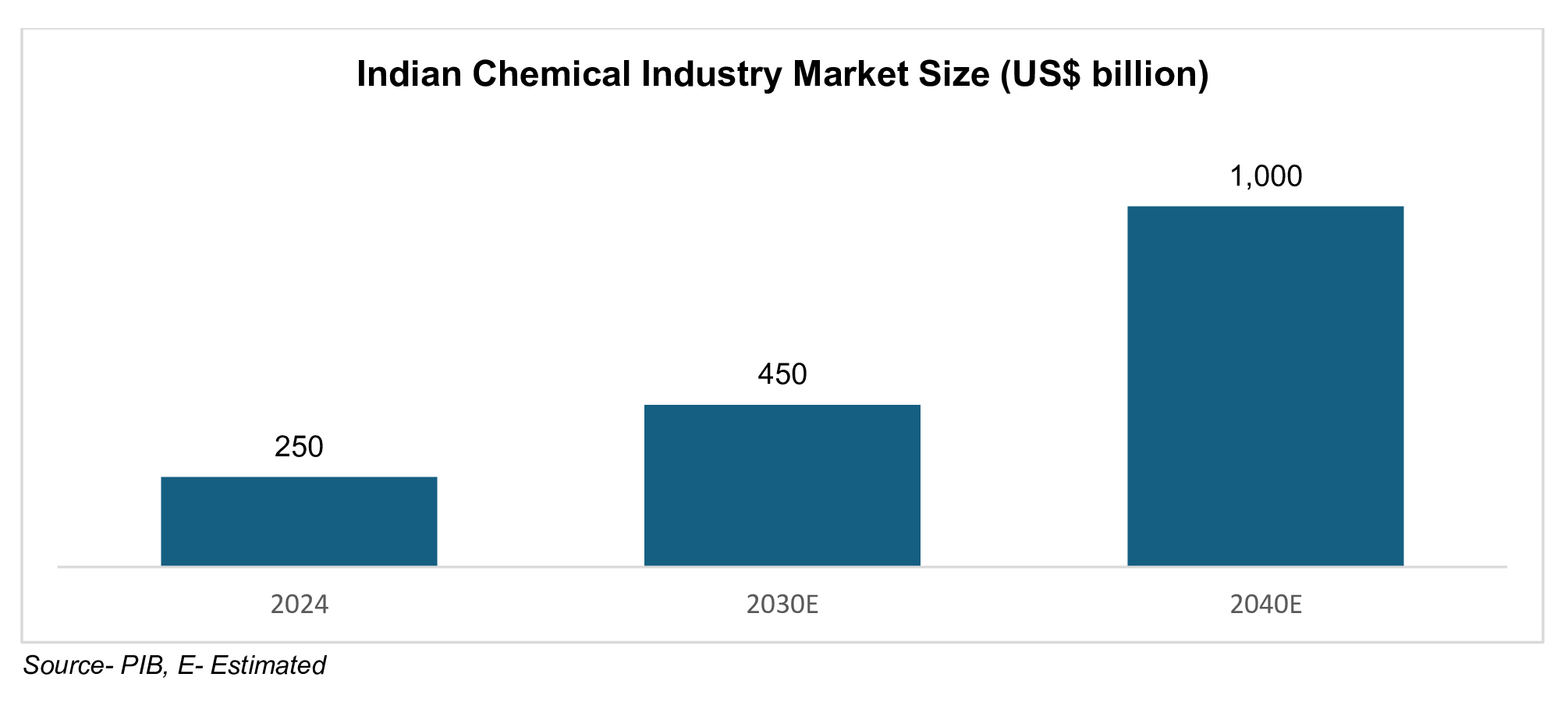

Market outlook

India’s chemical industry is valued at Rs. 21,50,750 crore (US$ 250 billion) in 2024 and is expected to rise to Rs. 35,26,800- 39,67,650 crore (US$ 400-450 billion) by 2030. With global demand rising, investments in downstream manufacturing, government incentives, and manufacturing, the sector expects to reach Rs. 86,03,000 crore (US$ 1 trillion) by 2040, which depicts a CAGR of around 9-10%. The exports are increasing, with dyes and dye intermediates adding Rs. 20,088 crore (US$ 2.3 billion) during April to February FY25. India’s ranking as the fourth largest agrochemical producer and as the producer of dyestuffs and intermediates further increases the likelihood of becoming a sustainable hub of high-value chemical manufacturing.

Shifts towards green chemistry and circular economy

The Indian chemical industry is slowly turning into a more sustainable one, and the emphasis is on green chemistry and the principles of the circular economy. The relocation of non-renewable petrochemical feedstock to biomass-based materials is one of the steps in this process, and it is supported by the BioE3 strategy, which supports sustainable biomanufacturing. India is also producing bio-based specialty chemicals, enzymes, and biopolymers using agricultural residues and industrial wastes. This reduces the dependence on petrochemicals and opens new frontiers of high-value and friendly products.

Green chemistry is not a new concept. It went global with the Responsible Care initiative in 1985, which was later adopted in India by the Indian Chemical Council (ICC). What was originally a level of compliance initiative is now part of a company strategy, with businesses actively considering sustainability as part of their business models. It focuses on eliminating harmful components, minimising waste, and developing less harmful processes through biotechnology, nanotechnology, and materials science. These technologies are helping the industry to solve wider social problems, including climate change, food security, and plastic pollution.

The circular economy, in its turn, can offer India enormous economic and environmental possibilities. The country generates about 62 million tonnes of waste annually, yet around half of this is deposited in landfills. By going circular, India can unlock enormous value. The Economic Advisory Council to the Prime Minister projects that in 2030 and 2050, it would amount to Rs. 19,22,106 crore (US$ 218 billion) per year and 55,01,808 crore (US$ 624 billion) per year, respectively.

Biodegradable plastics produced using renewable materials, bio-based industrial enzymes, and agrochemicals are feasible already. A green chemistry and circular economy model can help transform the industry by reducing emissions, optimising resource use, and building a more resilient and sustainable future.

Decarbonisation and digital transformation

The Indian chemical industry is at a critical sustainability point, with decarbonisation and digitalisation. Energy efficiency and carbon reduction have become the agenda of the sector. The Department of Chemicals and Petrochemicals estimates that the industry absorbs an estimated 13% of the total industrial energy consumption and approximately 6% of the total greenhouse gas emissions in India. In response to this effect, businesses are using cleaner fuels, electrifying their operations, and using carbon capture technologies. The major chemical belts in Gujarat and Maharashtra are investing heavily in captive renewable generation, and solar and wind infrastructure are supporting the decarbonisation goals. Firms such as Deepak Nitrite and SRF have indicated that they would like to reduce carbon intensity by over 20% in the next five years by 2030.

Artificial Intelligence (AI) and Machine Learning (ML) are transforming the Indian chemical industry through digitalisation. Predictive analytics, process optimisation, and real-time monitoring enhance efficiency, safety, and productivity. Some of the successful stories include Reliance Industries Limited, which implemented AI-based predictive maintenance in refineries, and Tata Chemicals, which implemented Internet of Things (IoT) and AI analytics to optimise the real-time processes. The technologies allow reduced downtime, reduced energy, improved product quality, and sustainable practices. As innovations such as autonomous chemical plants and digital twins approach, digitalisation and decarbonisation combined are making the Indian chemical industry an international powerhouse in terms of efficiency, innovation, and sustainable growth.

Policy support and industry collaboration

- FDI and investment growth: FDI inflow to the chemicals sector (excluding fertilisers) had topped Rs. 1,42,647 crore (US$ 23.2 billion) by FY25. By 2025, the estimated investment in the Indian chemicals and petrochemicals industry is of Rs. 8,00,000 crore (US 90.73 billion).

- Export and employment: Export earnings increased to Rs. 3,50,000 crore (US 39.7 billion) in 2024 compared to Rs. 1,65,000 crore (US 18.71 billion) in 2014. As of 2024, the industry hires approximately one million individuals. Oil and Chemical investments amounting to Rs. 35,14,000 crore (US 398.55 billion) provided 40,000 jobs. Also, Rs. 73,518 crore (US 8.34 billion) was spent on Paradip, a major industrial port city and municipality in the Jagatsinghpur district of Odisha, India.

- Policy and incentive support: Plans such as the National Chemical Policy, Green Chemistry initiative, Production-Linked Incentive (PLI) schemes, and development of CIPET are driving innovation, skills development, and sustainability.

- NITI Aayog scheme: Proposes world-class chemical hubs, port-based clusters, and operating expense (OPEX) subsidies to boost production and exports. It also highlights Research and Development (R&D) funding, faster environmental clearances, targeted Free Trade Agreements (FTAs), and specialised skill development to strengthen the sector.

- Green hydrogen mission: The Mission aims at the achievement of 5 MMT green hydrogen capacity per year by 2030, 6 lakh jobs, Rs. 1,00,000 crore (US$ 11.34 billion) of fossil fuel imports saved, and 50 MMT of greenhouse gas saved.

- Industry collaboration and sustainability: Green bonds and responsible care programmes are being adopted, which encourage environmentally responsible investments and align the industry with global ESG practices.

- Infrastructure and government spending: Union budget in 2025-26 budgeted the Ministry of Chemicals and Fertilisers at Rs. 1,61,965 crore (US$ 18.7 billion). The 2023 projects launched by the Prime Minister, Mr. Narendra Modi, valued at Rs. 50,700 crore (US$ 6.11 billion) further strengthened the growth of the sector.

The road ahead for India’s chemical industry

As a result of green chemistry innovations, bio-based materials, and circular economy practices, the Indian chemical industry is turning into a world leader in sustainable chemicals. The industry is also taking note of effective utilisation of resources, incorporation of renewable energy, and friendly production to the environment. It is seizing the benefits of capital in petrochemicals, specialty chemicals, and agrochemicals in domestic markets. Government support, investment incentives, research hubs, policy reforms, and stimulating academia, industry, and technology providers to work together are all improving local capabilities. Digitalisation and AI are making things more efficient, safer, and innovative, and green finance frameworks encourage environmentally friendly initiatives. India is not just reducing its reliance on imports, but it is also expanding its international footprint, which will close the gap in capabilities, infrastructure, and downstream manufacturing, resulting in a healthier, more sustainable, greener chemical industry in the decades to come.

FAQs

What is the significance of the chemical industry in India?

The chemical industry in India contributes significantly to GDP, supplies key inputs to agriculture, pharmaceuticals, textiles, and automotive sectors, and ranks among the top global producers.

How is India’s chemical industry moving towards a sustainable future?

Through green chemistry, circular economy practices, renewable energy adoption, and bio-based materials, the sector is reducing environmental impact while enhancing efficiency.

What role does digitalisation play in India’s chemical industry?

Digital tools, AI, and predictive analytics optimise processes, improve safety, reduce waste, and enhance productivity.

How is the government supporting sustainable growth in the chemical industry in India?

Through policies like the National Chemical Policy, PLI schemes, Green Hydrogen Mission, research hubs, and financial incentives for green initiatives.

What opportunities exist for global leadership in sustainable chemicals?

India can expand its global footprint in specialty chemicals, bio-based products, and petrochemicals by leveraging innovation, policy support, and sustainability initiatives.