Advantage India

Robust

Demand

*The Indian technical textiles market is expected to expand to US$ 23.3 billion by 2027, driven by increased awareness of goods and higher disposable incomes.

*Cotton production in India is projected to reach 7.2 million tonnes (~43 million bales of 170 kg each) by 2030, driven by increasing demand from consumers.

*The total exports during FY26 (April-June 2025) stood at US$ 9.40 billion, with RMG (45%), Cotton Textiles (30%), and Man-Made Textiles (12%) as key contributors.

Competitive

Advantage

*Abundant availability of raw materials such as cotton, wool, silk and jute.

*India enjoys a comparative advantage in terms of skilled manpower and in cost of production relative to other major textile producers.

*Union Minister of Commerce and Industry, Mr. Piyush Goyal, emphasised that the India–United Kingdom (UK) Free Trade Agreement (FTA) opens transformative opportunities for textiles, leather, and footwear sectors, enhancing competitiveness and visibility in the UK market.

Policy

Support

*100% FDI (automatic route) is allowed in the Indian textile sector.

*The Union Budget 2025-26 allocated Rs. 5,272 crore (US$ 607 million) for the Ministry of Textiles, a 19% increase from the previous year. It also introduced a five-year Cotton Mission to boost cotton productivity, reduce import dependence, and enhance MSME-driven textile competitiveness.

*Indian Council of Agricultural Research (ICAR) - Central Institute for Cotton Research (CICR) is implementing a special cotton project under the National Food Security and Nutrition Mission across eight major states from FY24 to FY26. The project promotes best practices to boost cotton productivity, with a total outlay of Rs. 6.03 crore (US$ 698,614).

Increasing

Investments

*Total FDI inflows in the textiles sector stood at Rs. 30,480 crore (US$ 4.72 billion) between April 2000-March 2025.

*According to Apparel Export Promotion Council (APEC), significant opportunities exist to deepen collaboration between Indian and Japanese firms in the textiles sector, with Tokyo-based companies expressing keen interest to invest in India.

Major Textiles hubs in India

- NCR

- Gujarat

- Maharashtra

- Uttar Pradesh

- West Bengal

- Tamil Nadu

- Madhya Pradesh

- Rajasthan

IBEF Campaigns

MORE

Aatmanirbhar Bharat Utsav 2024

Union Minister of External Affairs, Dr. S. Jaishankar and Union Commerce an...

Case Studies

MOREIBEF BLOG

MOREGrowing Power of India’s DIIs

India’s equity markets are experiencing a major structural shift. Dom...

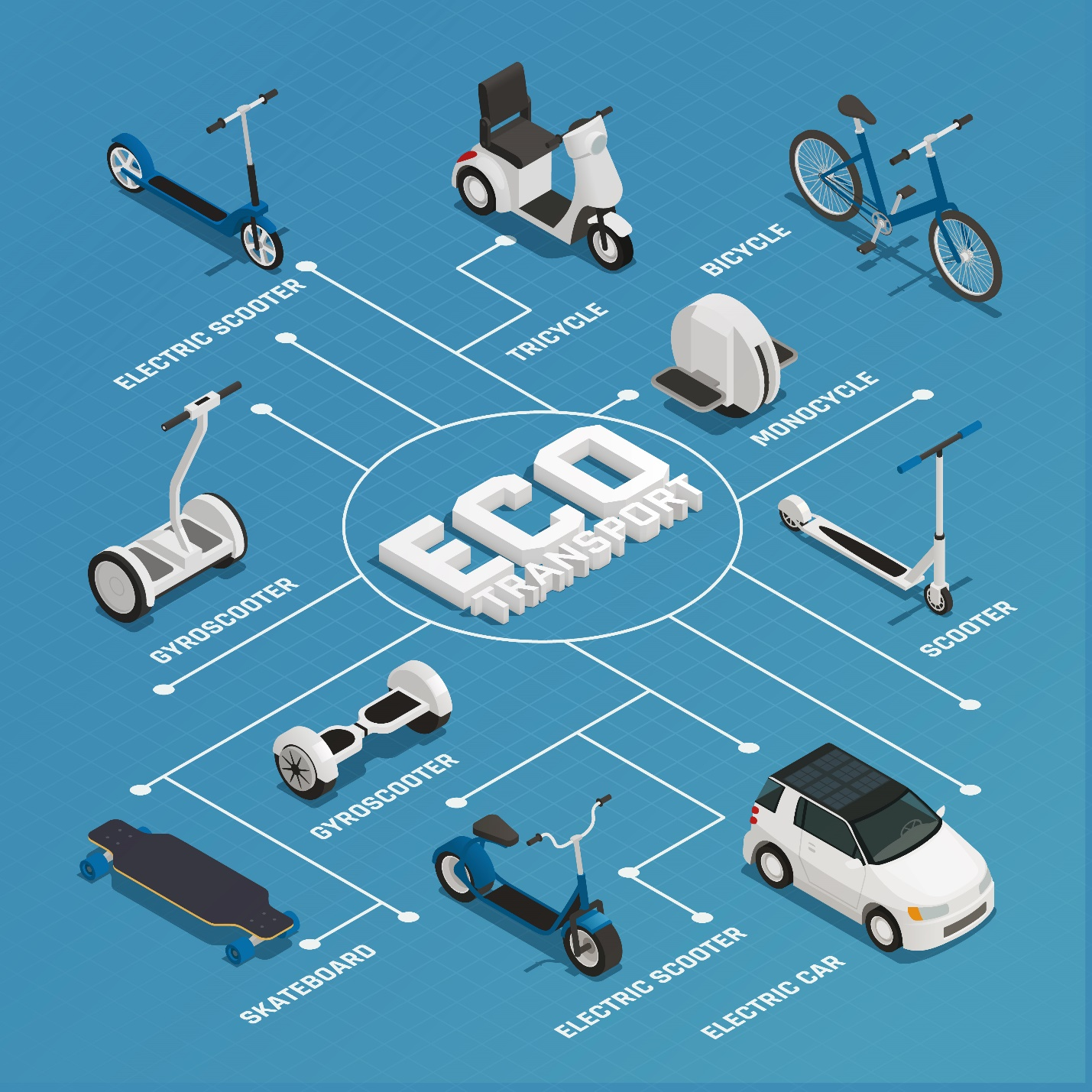

Electric Mobility in Secondary Cities: Beyond Delhi and Bengaluru

India’s electric vehicle (EV) revolution is gathering pace nationwide...

AI for Local Language - Inclusion through Vernacular Models

India, home to hundreds of languages and celebrated for its cultural divers...